* Hunting for esters

* Dip hopping

* Hop profile: Saaz family

* Additional reading

Welcome to Vol. 8, No. 6. The fresh hop festivals have come and gone, but plenty of fresh hop beers remain. Check out the results of the Best of Craft Beer Awards fresh hop competitions.

ISOBYTYRATES, HEXANOTES AND OTHER GOOD STUFF

There were many takeaways from a presentation at the World Brewing Congress titled, “Chemical and Sensory Evaluation of Hop Varieties: Insights into the Relationship Between Aroma Properties and Growing Regions.” Marcus Ojeda, an R&D chemist at Abstrax Tech, headed up the research behind the presentation, and when Ojeda couldn’t be in Minneapolis for the conference, Tom Nielsen stepped in to talk attendees through the PowerPoint.

Nielsen worked 20 years at Sierra Nevada Brewing and was research and development and raw materials manager before he left in February to join Abstrax Tech as director of brewing and beverage innovation. Abstrax Tech is known first for its botanically derived terpene blends and isolates that are native to cannabis. The company added a Hops Division last year.

The project was Ojeda’s first foray into hop chemistry. “It is interesting how he is characterizing hops, coming from a cannabis mind,” Nielsen said. For instance, Abstrax has developed an aroma spectrum, spanning exotic to savory, which Ojeda overlaid it onto hops. “A new way to show things,” Nielsen said.

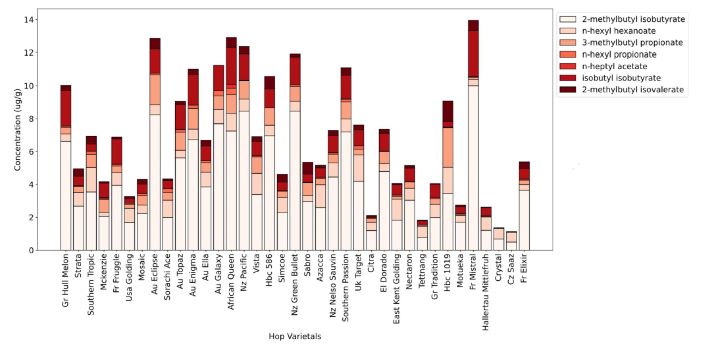

Bottom line, I’m looking forward to Abstrax sharing more research. For now, there is this chart.

Although Nielsen emphasized that the esters shown here do not by themselves account for exotic flavors—instead look to sulfur compounds (such as 4MMP/4SMP or 3MH/3SH)—notice there are significant differences from hop to hop. “There’s a little more to learn here,” Nielsen said.

Two of the esters charted are among the Yakima Chief Hops survivables, meaning that when they are added early in brewing process they may still survive in finished beers. They have high thresholds of perception, particularly compared to sulfur compounds, one reason they don’t have the same aroma/flavor impact. Nonetheless, they may add subtle fruity, although not necessarily tropical, character.

The Abstrax chart does not include Centennial, but if you toggle over to the survivables chart you’ll see that Mistral (French, but a daughter of Cascade) and Centennial (American) share a high level of 2-methybutyl isobutyrate. Several other hops do as well, particularly those from Australia. Or notice how similar Simcoe (mother) and Mosaic (daughter) are. Or Hallertau Mittelfrüh (grandmother) and Citra (granddaughter).

Enough fun. Here is what these esters may add to beer:

2-methybutyl isobutyrate: Fruity, apricot.

hexyl hexanote: Found in many fruits, including apples, passion fruit, plums, and citrus fruits. Also true of these other esters as well.

3-methylbutyl proprionate: Sweet fruits, banana, pineapple, ripe fruits.

hexyl proprionate: Fruity, melon, pear.

heptyl acetate: Fruity, pear.

isobutyl isobutyrate: Fruity, pineapple.

2-methlbutyl isovaletrate: Fruity, apple, pear, pineapple.

THE ORIGIN OF DIP HOPPING

A quick review of “dip hopping,” from Vol. 4, No. 8. Kirin Brewery in Japan began using the process in 2012 for its Grand Kirin beers. Basically, they made a slurry by steeping hops for about an hour at temperatures (150-170° F) lower than found in conventional whirlpooling, then added the slurry into wort before pitching yeast. Kirin learned that the resulting beers contained as much linalool as dry hopped beers but less myrcene (which itself may mask fruity aromas associated with linalool and other oxygenated compounds). This also reduced production of 2M3MB (an onion-like off flavor).

Kirin researchers saw little difference in hop enzymatic activity between dip-hopped beers and whirlpooled beers. (Not discussed is the implication that enzymes associated with hop creep that occurs during dry hopping may be denatured during dip hopping. If the process changed nothing else and it reduced hop creep that could be good enough reason for breweries to dry hop less and dip hop more.)

For brewers, the appeal is pretty simply: less isomerization than with whirlpooling and greater retention of some essential oil for biotransformation. In addition, drinkers have said they perceive a difference, a positive difference, in dip-hopped beer aroma and flavor.

In August at the World Brewing Congress, Tomonori Kano, who works in R&D at Kirin, explained why Japanese breweries began active fermentation dry hopping (dip hopping). It’s simple. Japanese Alcohol Tax Law requires that fermentation occurs after the ingredients are added.

HOP PROFILE: SAAZ FAMILY

A break this month with the typical hop profile, instead including new members of the Saaz family along with the original.

During the fourteenth century Emperor Charles IV decreed exporting hop cuttings from Bohemian plants punishable by death. “Seven hundred and fifty years ago somebody decided this was a great hop,” said John Henning, a research plant geneticist with the U.S. Department of Agriculture Agricultural Research Service in Oregon. That particular Bohemian plant could well have been an ancestor Saaz, but don’t call that Saaz spicing your favorite pilsner a direct descendant.

Karel Osvald, who made the clonal selections (clones 114, 31 and 72) for the Saaz grown today and initiated hop breeding in Czechia in the 1960s, wrote he was certain that Saaz had evolved.

“Current hop cultures are a mix of vegetative posterity of various genetic origins. Issue of varieties is absolutely unclear, and we can talk neither of Czech old-Saaz red-bine hops nor of Semš hops. Semš hops originate from old-Auscha hops, which comes from old-Saaz hops,” he wrote almost 100 years ago. “Today the cultures of hops are thoroughly mixed, even though there are no great differences between neighboring plants in a hop yard. Hops are plants that can adapt to growing conditions, since the soil and the climate lend them a certain character.”

When the totals are in from the 2024 harvest, it may turn out that Czech farmers harvested more tons of Saaz this year than any other aroma hop in the world. She is immensely popular although she does not yield as many kilos per hectare and is more susceptible to drought, heat and disease than new varieties with similar aroma qualities. Farmers still plant Saaz on 80 percent of their acres.

“A review of current knowledge” by those at the Research Institute of Brewing and Malting and breeders at the Hop Research Institute suggests they would like brewers to pay more attention to alternatives to the original that are better suited to deal with climate change. The basics and the heritage of each of them, with a description provided by the authors:

Saaz (3.2 alpha acids, 4.2 beta acids, .05 ml/100g essential oil). The original. “A traditional fine aroma hop with a typical fine hoppy aroma with a pronounced herbal scent and weak citrusy, fruity, spicy, and floral scents in the background.”

Saaz Late (3.1 alpha acids, 4.5 beta acids, .07 ml/100g oil). A progeny that has her origin in Saazer. “Has a characteristic fine hoppy aroma with a pronounced herbal and floral scent and weak fruity, spicy, and citrusy scents in the background.”

Saaz Brilliant (3.8 alpha acids, 2.7 beta acids, .05 ml/100g oil). Selected from a Saaz × male Saaz crossing. “Has a fine hoppy aroma with a pronounced herbal scent and weak fruity, citrusy, and spicy scents in the background.”

Saaz Comfort (5.6 alpha acids, 5.5 beta acids, .08 ml/100g oil). Selected from a Serebrianka × male Saaz crossing. “A fine hoppy aroma with a pronounced spicy and herbal scent and weak fruity scent in the background with traces of citrusy and floral scents.”

Saaz Shine (3.6 alpha acids, 2.9 beta acids, .08 ml/100g oil). Selected from a Sladek × male Saaz crossing. “A a rich but still fine hoppy aroma with a pronounced fruity and citrusy scent followed by a balanced herbal, floral, and spicy scent in the background.”

Saaz Comfort and Saaz Shine have very good resistance to fungal diseases and tolerance to drought. Their higher yield compared to the original Saaz (about 38 percent higher) is also significant.

ADDITIONAL READING

After the cones are gone. For every kilogram (2.2 pounds) of material inside the cones that can be used to brew beer, there are 3.5 kilograms (7.7 pounds) of wasted biomass from the rest of the plant. A startup in Germany plans to turn the biomass into products such as acoustic panels, thermal insulation and building boards.

Hop extracts for homebrewers? They are designed for commercial-size batches, but Annie Johnson found she likes the efficiency, and . . . “what I really loved about using these hop extracts was the effect on aroma and flavor—it was immediate, and that is powerful. I was able to adjust the level of hop intensity in a matter of minutes, which I found to be really cool.”

Oregon hops. Eric Sannerud declares up front that West Coast Hop Breeding is a client, but don’t let that stop you from reading his report from the Oregon hop harvest.